CUTTING TOOLS SINCE 1978

subsidiary of Norcosaw.com

we hope you like the site, enjoy!

Welcome to our newest BUY HERE - PAY HERE router bit site!

We're working hard adding cutting tool product each day. We have over 2,000 router bits to list. If you don't see what you're looking for, tell us in a quick email and we'll be happy to get it for you. We custom manufacture bits also..! Keep that in mind... Connect with us by message via email HERE. or give us a call 970-481-0033 , Thanks

U.S.A. TOUGH ROUTER BITS - READY FOR WORK!

ROUTER BIT SETS

ROUTER BITS with PROFILES

ROUNDOVER ROUTER BITS

STRAIGHT ROUTER BITS

SPIRAL ROUTER BITS

FLUSH TRIM ROUTER BITS

SLOTTING KERF CUTTING ROUTER BITS

STILE & RAIL ROUTER BITS

CARBIDE TIPPED HOLE SAWS

COUNTERSINKS AND TAPERED DRILLS

BALL BEARINGS

BRAD-POINT DOWEL BITS

THRU-POINT DOWEL BITS

HINGE BORING BITS

HEAR WHAT OUR WOODWORKING CUSTOMERS ARE SAYING

After buying a Ryobi set of router bits, I assumed that no matter what I bought I would always end up having to sand the routed surface. After doing a little research and reading some reviews, I found that that is not the case and most professionals agreed that Whiteside bits were the best out there and were reasonably priced.

After buying this set and testing them I agree whole-heartedly. The Ryobi

bits are a piece of junk. The Whiteside bits are awesome! They don't require ANY sanding after routing. The routed surface is so smooth you could almost see a shine in some woods. I definitely believe that you get what you pay for and in this case, you get more than what you pay for.

Verified Buyer

Been using this set of bits extensively for over 7 years. These bits are SOLID. The bits were used so far to custom make cabinets, trim, and molding for multiple homes and are still almost as good as new. They are expensive but they have been worth it. Very confident these will last a lifetime.

Verified Buyer

Whiteside is among the very best you can buy, and people that know routing will undoubtedly agree. You won't regret buying them

The bonus is that this is, in fact, an excellent selection of bits for someone just getting their feet wet. They are all bits that you're likely to use again and again. You can buy a bigger selection for a lot less money here or at the big box store, but you'll end up with a bunch of cheap bits, most of which you'll use once and never need again. Ask youself, do you want a $3 bit spinning at 25,000 rpm, inches in front of your face?

I have no connection to Whiteside or anyone else, just impressed with the quality and selection in this set.

Verified Buyer

How To Calibrate Your Machine

free checkup

Spindle RPM and Feed Rate Calculations

A precondition to obtain maximum machine performance, tool life and chipping efficiency is to balance the optimum chip removal, cutting speed and feed rate of a machine. The following article provides valuable information on how to maximize the machining performance.

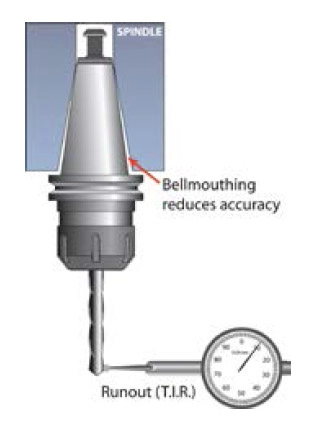

Spindle speed

Incorrect spindle speed is a common error in CNC machining. Each material and kind of machining requires an ideal tool profile and cutting speed. Larger tool diameters require slower cutting speeds. It is important to align spindle speed and feed rate for any given machining task to achieve the maximum quality, tool life and service life of the spindle. The spindle speed is hereby controlled by a frequency converter. All spindles are 3-phase asynchronous motors with an infinitely adjustable speed from 0 rpm to the maximum nominal speed.

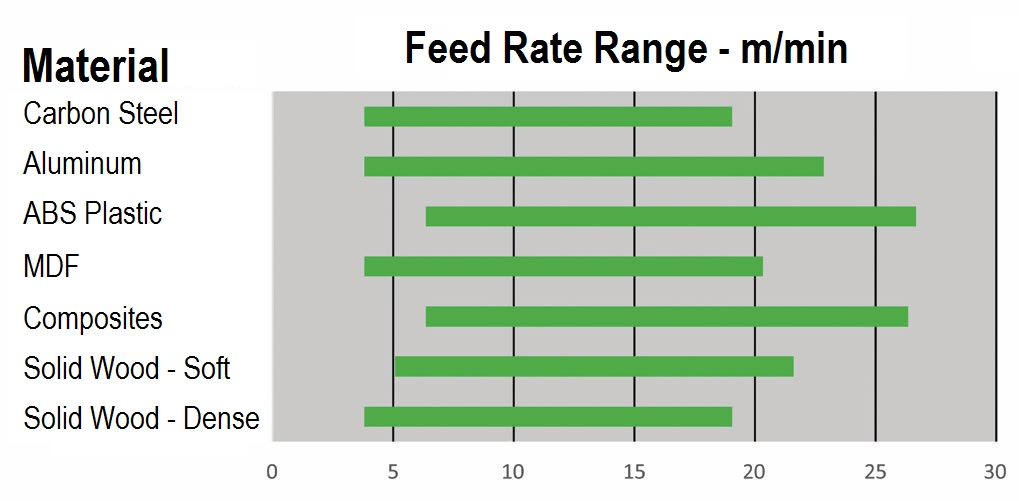

Feed rate

The feed rate of the cutting tool must be balanced proportionately to the spindle speed. Changing one factor influences the other factors. A too slowly set feed rate reduces the tool life of the cutting tool and might cause overheating and thus result in burn marks on the work piece. As a result, not enough material is removed and the cutting point is insufficiently cooled. The feed rate chart below provides information on starting point values. We recommend setting the specified mean values for the first start-up. Contact your cutting tool supplier for individual advice for your specific application.

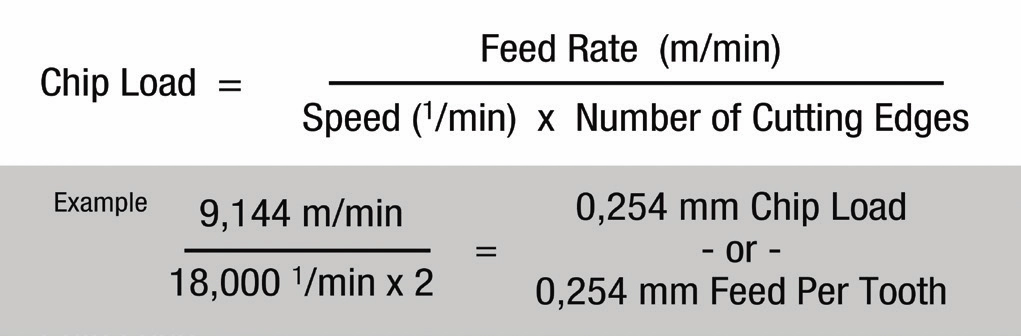

Chip Load

The chip load is a term used to describe the thickness of a chip removed perpendicular to the cutting direction, measured vertically to the cutting direction. The chip load is sometimes also referred to as "feed per tooth" and is calculated as follows:

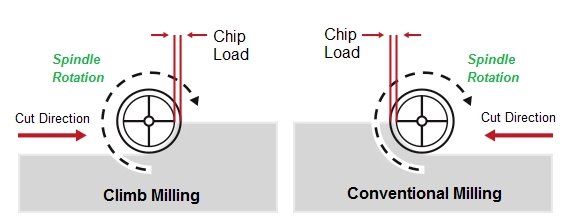

The chip load is an important factor to determine the cutting speed and the feed rate. As far as wood is concerned, a chip load that is too low causes too much heat on the cutting point. The “dust-like” chips may cause burn marks on the surface in turn. A chip load that is too high is pushing the cutter through the material causing too much pressure. The high radial loads on the spindle bearing resulting from that can cause spindle failure, excessive tool wear, and tool break over time. As far as milling is concerned, there are generally two kinds of milling: synchronous milling and conventional milling. For wood working, synchronous milling produces a better milling quality as the generated chips are torn out to a lesser extent. Synchronous milling should be preferred as loads are lower and tool life is longer.

The chip load is one of many factors used to determine spindle size and machine parameters, such as:

*Speed range and the power requirement for the spindle

*Determination of tool load depending on cutting tool model

*Calculation of torque for available application

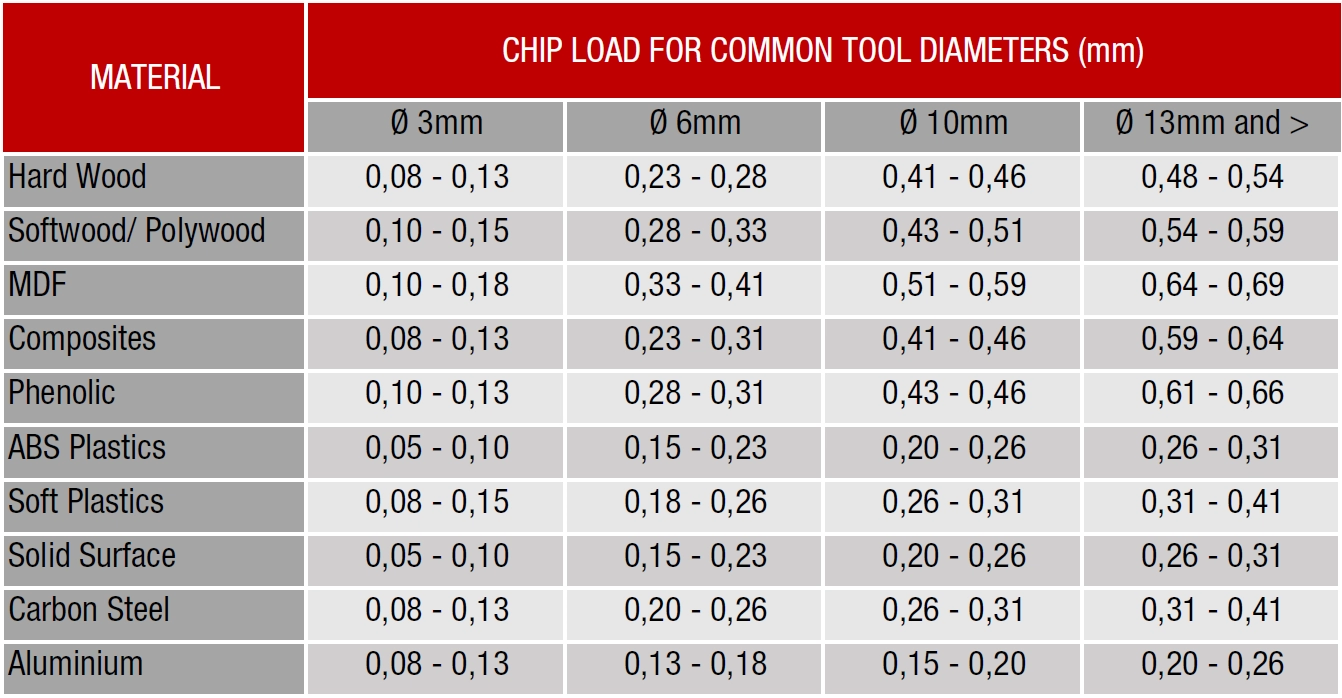

We recommend contacting a PDS applications technician in case of new spindle applications to support you in establishing the baseline cutting values. Our employees will be glad to answer your technical questions on the phone or by email. The chart below provides information on chip loads for common milling tools. These are “not to exceed” starting values for first time setups. Actual values may vary as a result of various machine factors, of course. These factors include: rigidity, power, tool clamping, spindle fixing, work piece clamping, and others.

As an exclusive 20 year distributor, we speak highly of Whiteside Machine. They have earned their ratings ...and they are:

a. Best for cut quality and b. Best value by Fine Woodworking magazine.

OUR PRODUCTS ARE USA MANUFACTURED

WITH PRECISION CNC EQUIPMENT AND INSPECTED WITH HIGH QUALITY VALIDATION AND PRIDE

Through word of mouth, hard work and a focus on quality, Northern Colorado Saw & Carbide products and services have expanded to supply business and hobbyists throughout the USA. Made from high quality steel and tipped with micro-grain carbide, we bring you a full line of router bits you will cherish and a pro service center to keep you sharp.

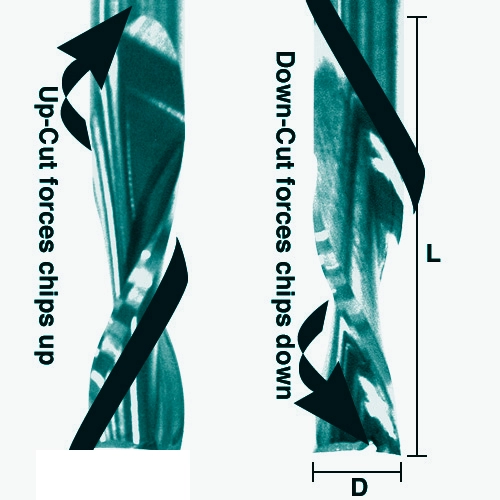

Our Spiral Router Bits were originally designed for the CNC industry as a tool for long life, under rigorous working conditions. As spirals became popular with the everyday woodworker and craftsman, an increase in demand was seen throughout the industry. DenverRouterBits offers a variety of spirals in up-cut, down-cut and compression flute designs. We recommend up-cut spirals for best routering control and ejecting chips up and out of your cuts. Down-cuts provide superb control with fraying on the surface nearest the router, while preventing the lift of small work pieces. Compression spirals have up and down flutes to maintain the cleanest cut on both the top and bottom of the work piece. We increase the life and value of your spiral selection by offering these bits in a solid carbide form.

DenverRouterBits is proud to supply the industry with such a superior line of drilling and boring tools. We offer a range of countersinks, manufactured with standard carbon steel or high speed steel, for extended life. Three wing drills and patented carbide-tipped wholesaws are among the line. Many of these tools were designed and tested by experts in the field.

DenverRouterBits is proud to supply the industry with such a superior line of drilling and boring tools. We offer a range of countersinks, manufactured with standard carbon steel or high speed steel, for extended life. Countersink Heads are designed to slip over the drill bit and affix with dual set screws into the flutes. Adjust the drilling length by sliding the head up or down the bit. Use to countersink holes in wood, plastic, or aluminum for flat head screws. Upgrade to the High Speed Steel series for longer life, especially in fiberglass or other abrasive materials. Matching drill bits are offered for your convenience. Many of these tools were designed and tested by experts in the field.

Sign Up For Tool Deals

sharpest deals you ever saw

Store Address

Fort Collins, Colorado 80524

We accept

An item was added to cart!

An item was added to cart!